Unleash exceptional finishing power with the sia Abrasives 6130 siafleece hd PTX Brush Wheel. Measuring ø 100 x 105 x 19mm, this high-performance abrasive wheel is engineered for versatility and durability. Its remarkable flexibility allows you to effortlessly tackle intricate contours and hard-to-reach areas, ensuring a consistently smooth and burr-free sanding pattern across any workpiece.

Experience extended operational life thanks to the PTX wheel’s optimised grain distribution throughout the fleece, which also contributes to its impressive tearing resistance. Say goodbye to frustrating clogging, allowing for uninterrupted workflow whether you’re working wet or dry. Achieve professional-grade results with this robust and reliable sia 6130 siafleece hd PTX brush wheel, designed to enhance your sanding efficiency and deliver a flawless finish every time.

| Grit | Bosch Part Number | sia Abrasives Part Number | Delivery | Pack Size | Sales Unit |

| Coarse | F 03E 007 8R2 | 0020.9050.01 | UK Stock (Next Day) | 1 | 1 Pack |

| Medium | F 03E 007 8R3 | 0020.9051.01 | UK Stock (Next Day) | 1 | 1 Pack |

| Fine | F 03E 007 8R4 | 0020.9052.01 | UK Stock (Next Day) | 1 | 1 Pack |

| Very Fine | F 03E 007 8R5 | 0020.9053.01 | UK Stock (Next Day) | 1 | 1 Pack |

| Micro | F 03E 007 8R6 | 0020.9054.01 | UK Stock (Next Day) | 1 | 1 Pack |

sia Abrasives’ 6130 siafleece hd PTX Brush Wheel is your versatile solution for a range of surface finishing applications. In stainless steel fabrication, it excels at creating a consistent, matt finish on grained surfaces, delivering a sophisticated aesthetic. It’s also ideal for achieving a smooth, satin finish on various materials, enhancing their visual appeal.

Beyond aesthetics, this sia PTX brush wheel is crucial in preparing surfaces for subsequent processes. It effectively finishes surfaces to the required standard for both coating and electroplating, ensuring optimal adhesion and a flawless final product. For stainless steel welds, it efficiently removes unsightly blueing, restoring a uniform appearance.

Furthermore, this wheel proves its utility in removing light oxide layers and performing light deburring tasks, leaving clean and smooth edges. Even minor casting seams can be effectively eliminated, resulting in a refined final form. Whether you require a specific finish or need to prepare surfaces for further treatment, the sia Abrasives 6130 siafleece hd PTX Brush Wheel offers reliable and consistent performance across diverse applications.

- Finishing of stainless steel on grained surfaces (matt finish)

- Satin finishing of surfaces

- Finishing to prepare for coating and electroplating

- Weld blueing removal from stainless steel

- Removal of light oxide

- Light deburring

- Removal of casting seams

sia Abrasives’ 6130 siafleece hd PTX Brush Wheel demonstrates its versatility across a broad spectrum of metallic materials. For unalloyed and low-alloy steels, it’s adept at surface preparation, achieving desired finishes, and light deburring tasks. When working with high-alloy steels, its robust construction ensures effective material removal and the creation of consistent surface textures without compromising the integrity of the alloy.

In the realm of non-ferrous metals, this abrasive wheel provides controlled abrasion for cleaning, satin finishing, and preparing surfaces for further processing like painting or anodizing. It handles ferrous metals with equal proficiency, making it a valuable tool for general metalworking applications. Specifically for stainless steel (inox), it excels in achieving both grained and satin finishes, as well as removing weld discoloration and light oxides, maintaining the material’s corrosion resistance and aesthetic appeal. Its adaptability makes it an indispensable abrasive solution for various metal types.

- Unalloyed / low-alloy steel

- High-alloy steels

- Stainless steel (inox)

- Non-ferrous metal

- Ferrous metal

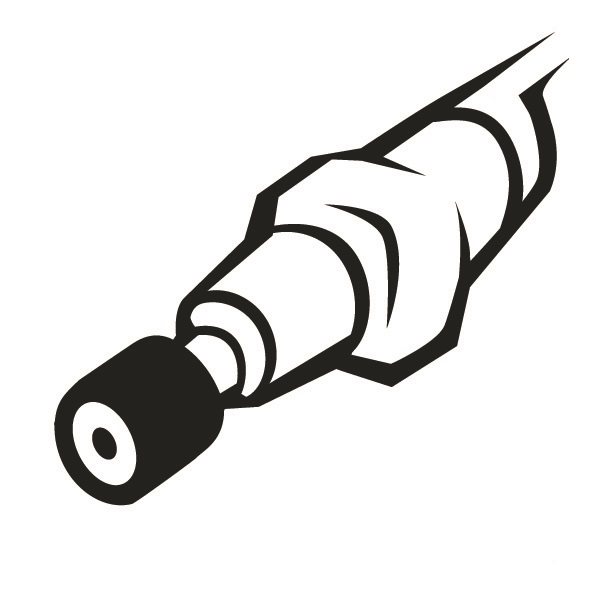

sia Abrasives 6130 siafleece hd PTX Brush Wheel is a grinding tool that is commonly used to grind surfaces such as Non-ferrous metal, High-alloy steels, Unalloyed and Low-alloyed steel. To use a 6130 siafleece hd PTX Brush Wheel effectively:

- First, ensure that the die grinder is unplugged, or the battery is removed to prevent any accidental starts.

- Wear appropriate personal protective equipment, such as safety glasses and gloves.

- Confirm that the 6130 siafleece hd Flap Wheel is compatible with your die grinder. Check the specifications and recommendations provided by both the flap wheel and die grinder manufacturers.

- Examine the die grinder to ensure it’s in good working condition. Confirm that the spindle and collet are clean and undamaged.

- Choose the collet size that matches the diameter of the spindle on the die grinder. The collet is the component that holds the accessory in place.

- Place the ø 100 x 105mm siafleece Flap Wheel onto the spindle of the die grinder. Ensure that it is centred and aligned properly.

- Slide the collet over the spindle and the flap wheel. Thread the collet nut onto the die grinder spindle and hand-tighten it. To secure the flap wheel in place, use a wrench to tighten the collet nut.

- Follow the die grinder manufacturer’s recommendations for the amount of torque applied.

- Ensure that the flap wheel is securely attached by giving it a gentle tug. If it doesn’t move, you’ve successfully attached the siafleece Flap Wheel.

- Before operating the die grinder, double-check to ensure that everything is securely in place and there are no loose components.

- Always adhere to the safety guidelines provided by the die grinder and flap wheel manufacturers. This includes using appropriate RPM settings and avoiding excessive pressure during operation.

By following these steps and referring to the specific instructions provided by the manufacturers, you can safely and effectively attach a sia Abrasives 6130 siafleece hd PTX Brush Wheel to a Die Grinder for your sanding needs.

Reviews

There are no reviews yet.