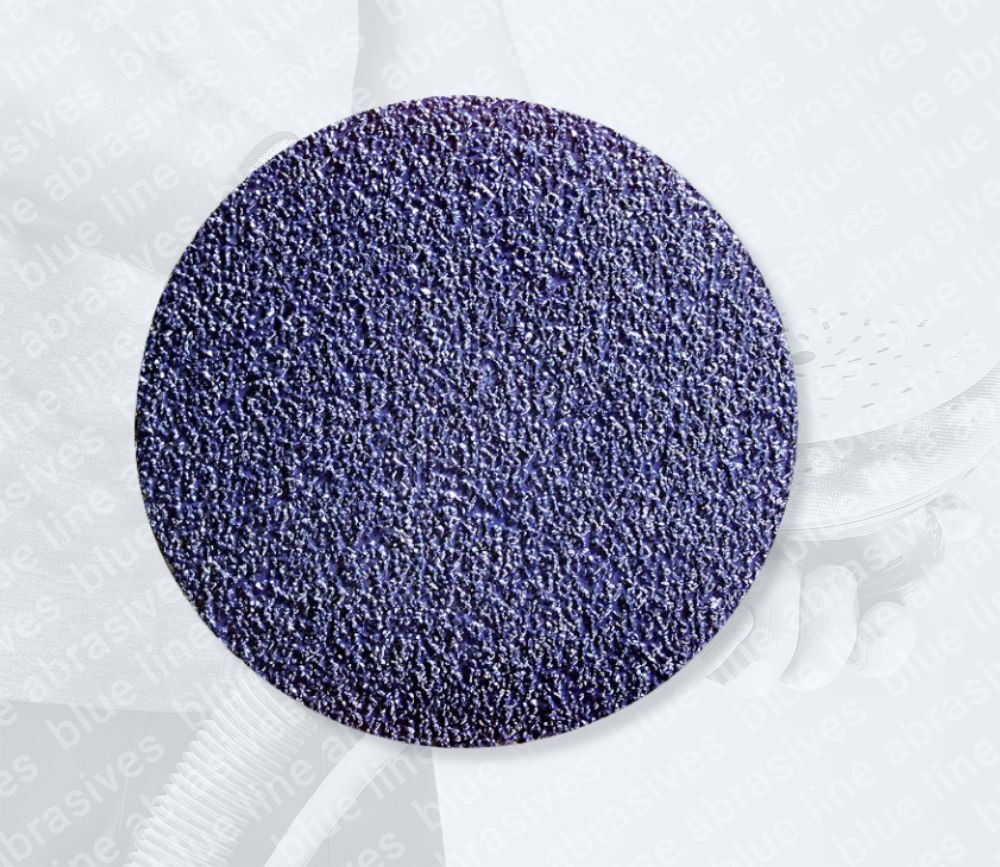

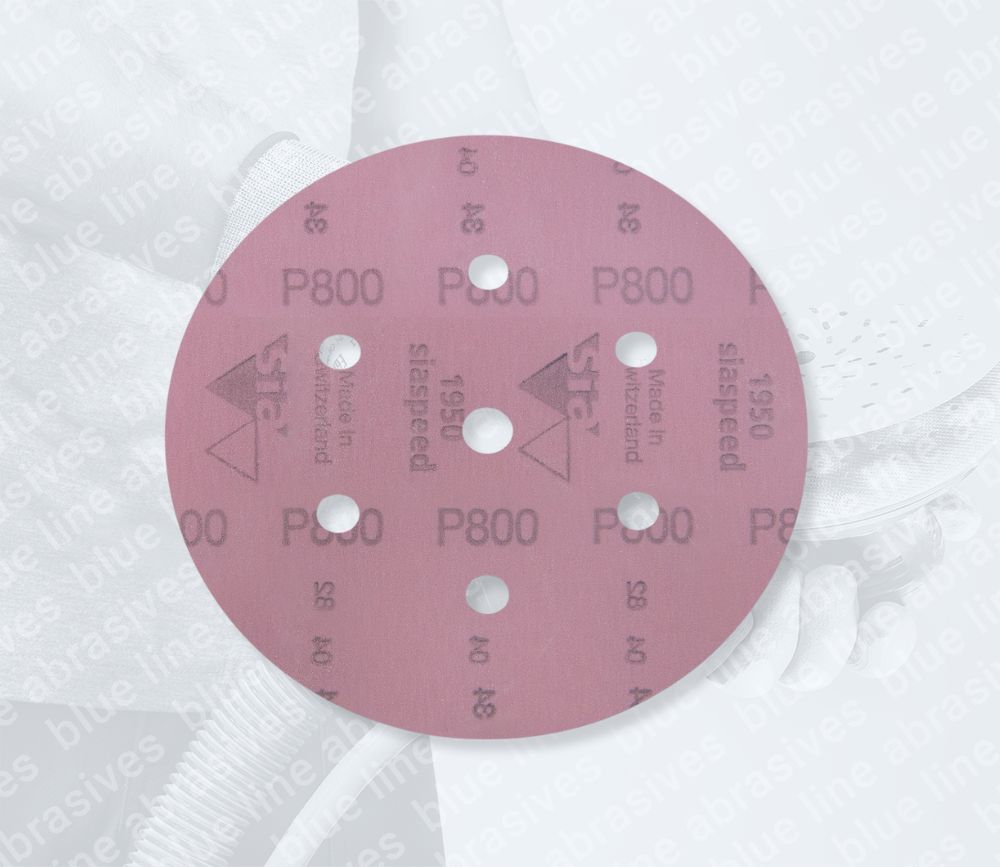

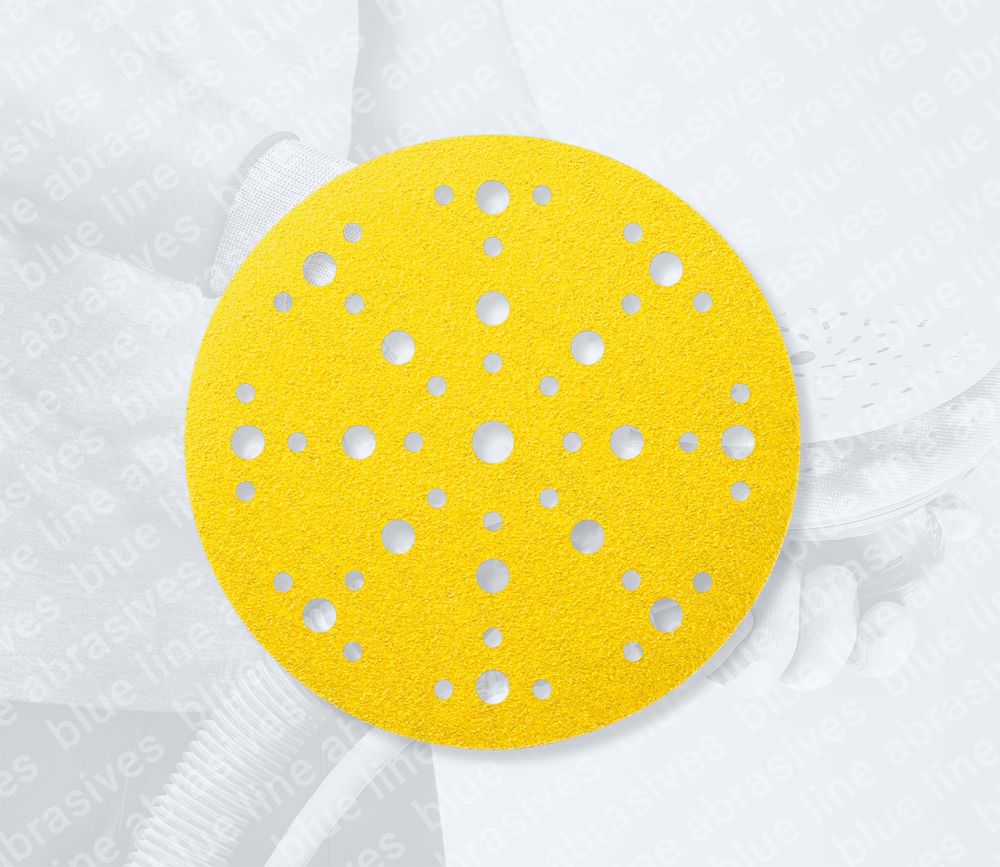

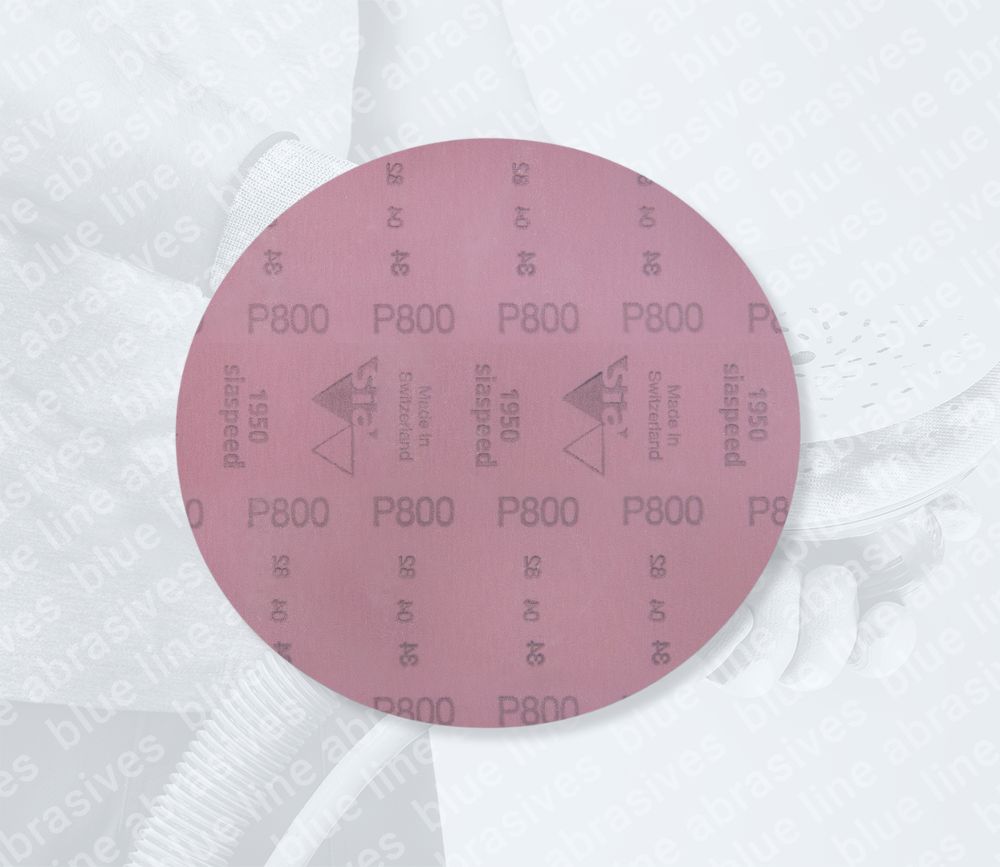

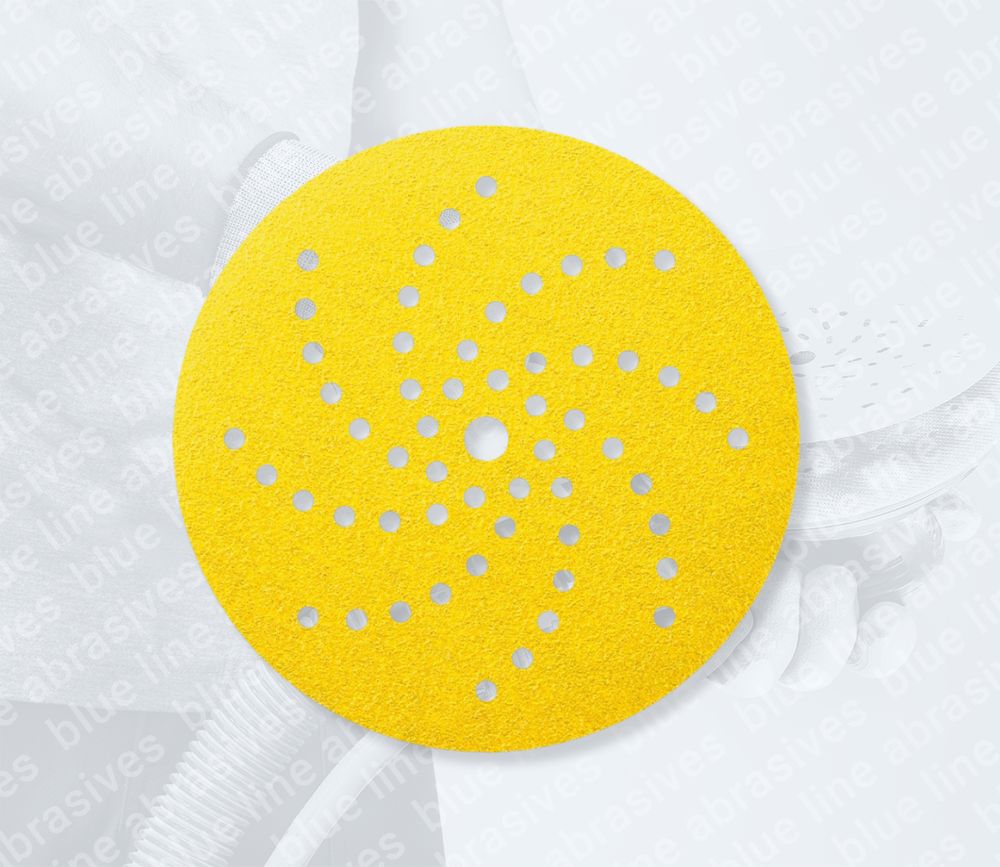

Experience a new era of abrasive technology with sia Abrasives 1550 siapower S-performance hook & loop sanding discs. Engineered for unparalleled efficiency, this innovative abrasive disc delivers optimised process steps and the highest stock removal rate in its class. Adopting mixed grit technology, its advanced grit mix, featuring ceramic aluminium oxide, ensures exceptional performance across a wide range of grits (40-220). Say goodbye to clogging, even when sanding lacquer with grits 400-600.

sia’s 1550 siapower S-performance disc is built to last. Its sustainable FSC paper backing, tailored to specific grit and application needs, provides remarkable durability and longevity.

From bodyfiller to varnish, this abrasive excels in dry sanding applications. Embrace greater efficiency, superior performance, and a commitment to sustainability with sia 1550 siapower – the future of abrasive technology.

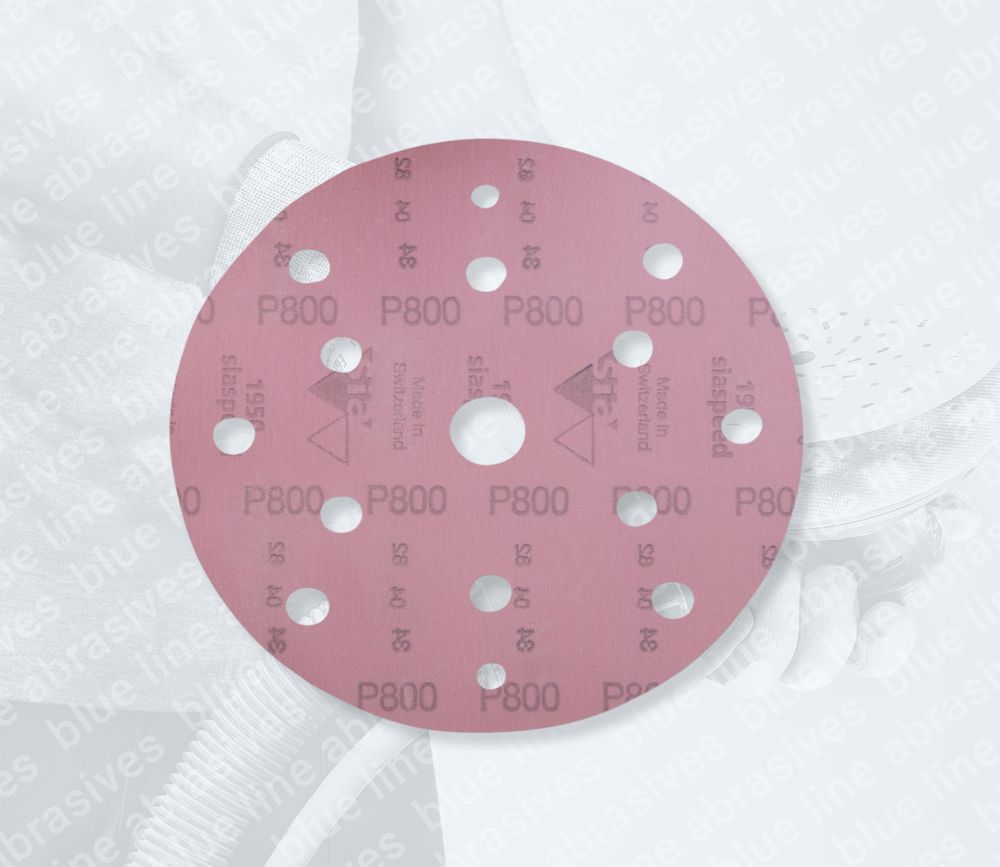

It is ideal for use with a Random Orbital Sander with a diameter of 150mm and either a 57 or 81-hole configuration sia S-Performance backing pad, depending on your chosen grit size.

| Grit | Bosch Part Number | sia Abrasives Part Number | Delivery | Pack Size | Sales Unit |

| P40 (57-Hole) | F 03E 008 KT0 | 2880.1926.0040.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P60 (57-Hole) | F 03E 008 KT1 | 2880.1926.0060.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P80 (57-Hole) | F 03E 008 KU9 | 2880.1926.0080.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P120 (81-Hole) | F 03E 008 KV1 | 9777.6618.0120.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P180 (81-Hole) | F 03E 008 KV3 | 9777.6618.0180.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P240 (81-Hole) | F 03E 008 KV5 | 9777.6618.0240.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P320 (81-Hole) | F 03E 008 KV6 | 9777.6618.0320.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P400 (81-Hole) | F 03E 008 KV7 | 9777.6618.0400.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P500 (81-Hole) | F 03E 008 KV8 | 9777.6618.0500.01 | UK Stock (Next Day) | 50 | 1 Pack |

| P600 (81-Hole) | F 03E 008 KV9 | 9777.6618.0600.01 | UK Stock (Next Day) | 50 | 1 Pack |

sia Abrasives 1550 siapower S-performance sanding disc is a versatile and high-performance abrasive solution for automotive refinishing professionals. Its exceptional stock removal, minimal clogging, and long lifespan make it an ideal choice for various applications, from coarse sanding to fine finishing and blending. By choosing sia’s 1550 siapower abrasive discs, technicians can streamline their workflow, enhance productivity, and achieve consistently superior results while contributing to a more sustainable future.

Sanding of Coatings and Impurities

- Efficient Removal: High stock removal rate and optimised process steps ensure swift and effective removal of coatings and impurities, minimising sanding time and effort. Its advanced grit mix delivers consistent results across a variety of surfaces.

- Reduced Clogging: Minimal clogging, particularly in the lacquer sanding grit range (400-600), further enhances efficiency and prevents premature abrasive wear, ensuring a smooth and consistent finish.

Sanding Out Unevenness at the Edges of Repaired Surfaces

- Precision and Control: The abrasive disc’s carefully tailored paper backing, combined with its exceptional grit mix, provides the precision and control needed to address unevenness at repair edges seamlessly. This ensures a smooth transition between repaired and original surfaces.

- Durability: Long lifespan in dry sanding applications enables consistent performance throughout the repair process, reducing the need for frequent abrasive changes.

Flatting of Bodyfiller and Composite Materials

- Aggressive Stock Removal: High stock removal rate quickly and efficiently flattens bodyfiller and composite materials, minimising labour and maximising productivity. Its optimised grit mix delivers a uniform finish, preparing surfaces for subsequent refinishing steps.

- Longevity: The pad’s extended lifespan ensures consistent performance even on challenging substrates, reducing downtime and abrasive consumption.

Fine Sanding of Primer Filler

- Smooth and Consistent Finish: The combination of a carefully balanced grit mix and tailored paper backing produce a smooth and consistent finish on primer filler, creating an ideal surface for subsequent paint application.

- Minimal Clogging: Reduced clogging in the fine grit range ensures a clean and even finish, preventing imperfections and rework

Keying of Old and New Lacquers

- Controlled Keying: Precise grit distribution and controlled cutting action provides optimal keying of both old and new lacquers, ensuring excellent adhesion for subsequent paint layers.

- Reduced Dust: Minimal clogging and efficient dust removal contribute to a cleaner working environment and reduced post-sanding clean-up.

Producing a Matt Finish on Old and New Lacquers for Blending

- Uniform Matt Finish: Even grit distribution creates a uniform matt finish on lacquers, ideal for blending repairs seamlessly into surrounding areas.

- Adaptability: sia 1550 siapower’s range of grits allows for fine-tuning of the desired matt finish, providing flexibility and control during the blending process.

- Sanding of coatings and impurities

- Sanding out unevenness at the edges of repaired surfaces

- Flatting of bodyfiller and composite materials

- Fine sanding of primer filler

- Keying of old and new lacquers

- Producing a matt finish on old and new lacquers for blending

sia Abrasives 1550 siapower S-performance disc’s innovative design and advanced grit mix make it suitable for a wide range of materials commonly encountered in automotive refinishing and other applications:

Paints and Coatings

- Colour: Efficiently removes imperfections and creates a smooth surface on colour coats, ensuring a flawless finish before applying clear coat. It’s also effective for featheredging and blending repairs.

- Lacquer: The disc’s clog-resistant properties make it ideal for sanding lacquer, delivering a smooth and even surface while minimising dust and debris.

- Old Lacquer: Effectively keys old lacquer, promoting adhesion for new paint layers and ensuring a durable, long-lasting repair.

Preparation Layers

- Primer Coat: Removes minor imperfections and creates a uniform surface on primer coats, preparing them for topcoat application.

- Primer Filler: Efficiently sands and levels primer filler, ensuring a smooth and even base for subsequent paint layers.

- Epoxy Primer Coat: The disc’s versatility extends to sanding epoxy primer coats, providing the necessary surface preparation for optimal adhesion and corrosion resistance.

- Cathodic Dip Primer Coat: High durability and clog resistance make the disc suitable for sanding even challenging substrates like cathodic dip primer coats.

Body Repair Materials

- Bodyfiller: High stock removal rate quickly and efficiently shapes and levels bodyfiller, minimising labour and maximising productivity.

Other Materials

- Plastics: Controlled cutting action and clog resistance make it suitable for sanding various plastic components, ensuring a smooth and even finish.

- Acrylic Glass: sia 1550 siapower discs can be used with caution on acrylic glass, requiring a light touch and fine grits to avoid scratching or damaging the surface.

- Gelcoat Polyester: Effectively removes imperfections and prepares gelcoat polyester surfaces for further finishing or repair.

- Glass-fibre Reinforced Plastic (GRP): High durability and cutting power make it suitable for sanding GRP components, ensuring proper surface preparation for subsequent coatings or repairs.

- Acrylic glass

- Bodyfiller

- Cathodic dip primer coat

- Colour

- Epoxy primer coat

- Gelcoat polyester

- Glass-fibre reinforced plastic (GRP)

- Lacquer

- Old lacquer

- Plastics

- Primer coat

- Primer filler

sia Abrasives 1550 siapower S-performance disc are suitable for sanding with a 150 mm diameter Random Orbital Sander on various objects, including Primers, Lacquers and Plastics. For effective use, select the appropriate grit, attach it to a pad, align holes, apply even pressure, and sand in a back-and-forth or circular motion. Keep it moving to prevent uneven spots or scratches. Periodically check and clean for desired smoothness.

Start by choosing the right grit for the material you’re sanding with SIA’s 1550 siastrong Disc. Attach it to a compatible sanding pad on your power tool. Sand in a back-and-forth or circular motion, applying even pressure and ensuring constant motion to prevent uneven spots or scratches. Periodically check and clean for desired smoothness.

For a list of compatible manufacturers and models of ROS machines please see below (Please note the correct backing pad is required):

AEG EX 150 E, AEG EX/E 450, AEG EXE 460 – 150, AEG ROS 150 E, Atlas Copco G2438-10Velcro6 Pro, Atlas Copco G2438-6.10C Pro, Atlas Copco G2438-6.10I Pro, Atlas Copco G2438-6.10N Pro, Atlas Copco G2438-6.3C Pro, Atlas Copco G2438-6.3I Pro, Atlas Copco G2438-6.3N Pro, Atlas Copco G2438-6.5C Pro, Atlas Copco G2438-6.5I Pro, Atlas Copco G2438-6.5N Pro, Atlas Copco LST 20 R625, Atlas Copco LST 20 R650, Atlas Copco LST 22 R625, Atlas Copco LST 22 R625-9, Atlas Copco LST 22 R650, Atlas Copco LST 22 R650-9, Atlas Copco LST 30, Atlas Copco LST31 H90-15, Atlas Copco LST32 H090-15, Atlas Copco LST32 S090-15, Atlas Copco R650, Atlas Copco TXE 150, Bosch GEX 150 AC/E, Bosch GEX 150 AE, Bosch GEX 150 Turbo, Bosch PEX 15 AE, Bosch PEX 420 AE, De Walt D 26410, De Walt DW443, De Walt ES 56 E, De Walt ES 56 EK, Fein M 10000-6, Fein MSf 636-1, Fein MSf 649-2 a/b, Fein ROT 14-200 E, Fein X 1107 VE, Felisatti RGF 150/600 E, Felisatti TP 521/AS, Felisatti TP 521/E, Felisatti TP 522 AS/CE, Festool ET 2 E – Plus, Festool ET 2 E, Festool ETS 150/3, Festool ETS 150/5 EQ, Festool ETS 150/5 EQ-Plus, Festool ETS 150/5, Festool ETS 150/S EQ-E, Festool ETS EC 150/3, Festool ETS EC 150/5, Festool LEX 150, Festool LEX 3 150/3, Festool LEX 3 150/5, Festool LEX 3 150/7, Festool RO 50 DX, Festool RO 150 E, Festool RO 150, Festool RO 2 E-Plus, Festool WTS 150/7 E, Festool WTS 150/7 E-Plus, Flex X 1107 VE, Flex XS 1107 VE, Hilti WFE 150, Hilti WFE 380, Hilti WFE 450 E, Hitachi SAY 150 A, HOLZ HER 2445, Kress 900 HEX /2, Kress 900 MPS, Mafell UT 150 E, Mafell UX 150 E, Makita BO 6030, Makita BO 6040 J, Metabo SX E 425 XL, Metabo SX E 450 DUO, Metabo SX E 450 TURBOTEC, Milwaukee ROS 150 E, Mirka DEROS 5650CV, Mirka DEROS 625CV, Mirka DEROS 650CV, Mirka DEROS 680CV, Mirka PROS 625CV, Mirka PROS 650CV, Mirka PROS 650DB, Mirka PROS 680CV, Mirka ROS 625CV, Mirka ROS 625DB, Mirka ROS 650CV, Mirka ROS 650DB, Mirka ROS2 610CV, Mirka ROS2 650CV, Peugeot PRX 150 E, Pro Tool ESP 150 E, Stayer LRT 150, Stayer RO 150 E, Wegoma RT188N, Wegoma RTE146L, Wegoma RTE46L, Wegoma RX91C

Reviews

There are no reviews yet.