Automotive applications demand high-performance abrasives to meet the industry’s stringent standards and achieve excellent results. Whether it’s for surface preparation, paint removal or polishing, selecting the right abrasive is crucial.

In this article, we will compare different types of abrasives commonly used in automotive applications, exploring their unique properties, advantages, and suitable uses. By understanding these differences, you can make informed decisions when choosing abrasives for your automotive projects.

Aluminium Oxide

Aluminium Oxide is one of the most widely used abrasives in the automotive industry. It is a durable and versatile abrasive with excellent cutting power and a long lifespan.

Aluminium Oxide abrasives are ideal for tasks such as paint and rust removal, surface blending, and shaping. They are available in various grit sizes, allowing for precise control over the material removal rate and achieving desired surface finishes.

sia Abrasives 1950 siaspeed is the perfect Aluminium Oxide abrasive for the Automotive industry.

Aluminium Oxide

Aluminium Oxide is one of the most widely used abrasives in the automotive industry. It is a durable and versatile abrasive with excellent cutting power and a long lifespan.

Aluminium Oxide abrasives are ideal for tasks such as paint and rust removal, surface blending, and shaping. They are available in various grit sizes, allowing for precise control over the material removal rate and achieving desired surface finishes.

sia Abrasives 1950 siaspeed is the perfect Aluminium Oxide abrasive for the Automotive industry.

Silicon Carbide

Silicon Carbide abrasives are known for their hardness and sharpness. They are particularly effective in automotive applications that require aggressive material removal or cutting.

Silicon Carbide abrasives are commonly used for tasks like sanding body filler, fiberglass, and plastic, as well as for polishing and finishing metal surfaces. They are available in different grit sizes and can withstand high heat levels, making them suitable for heavy-duty automotive applications.

sia’s 1748 sialac is the perfect Silicon Carbide abrasive for the Automotive industry.

Silicon Carbide

Silicon Carbide abrasives are known for their hardness and sharpness. They are particularly effective in automotive applications that require aggressive material removal or cutting.

Silicon Carbide abrasives are commonly used for tasks like sanding body filler, fiberglass, and plastic, as well as for polishing and finishing metal surfaces. They are available in different grit sizes and can withstand high heat levels, making them suitable for heavy-duty automotive applications.

sia’s 1748 sialac is the perfect Silicon Carbide abrasive for the Automotive industry.

Ceramic Abrasives

Ceramic abrasives are a newer development in the automotive industry and are highly regarded for their exceptional durability and heat resistance. These abrasives are engineered to provide fast cutting and extended life, making them ideal for demanding applications like grinding and stock removal on hard metals.

Ceramic abrasives maintain their cutting edge even under high heat, making them well-suited for automotive tasks that involve heavy material removal.

sia Abrasives 7500 sianet CER is the perfect Ceramic abrasive for the Automotive industry.

Ceramic Abrasives

Ceramic abrasives are a newer development in the automotive industry and are highly regarded for their exceptional durability and heat resistance. These abrasives are engineered to provide fast cutting and extended life, making them ideal for demanding applications like grinding and stock removal on hard metals.

Ceramic abrasives maintain their cutting edge even under high heat, making them well-suited for automotive tasks that involve heavy material removal.

sia Abrasives 7500 sianet CER is the perfect Ceramic abrasive for the Automotive industry.

Diamond Abrasives

Diamond abrasives are the hardest and most precise type of abrasive available. They offer superior performance in automotive applications that require fine detailing, precision cutting, and polishing.

Diamond abrasives excel in tasks like glass and windshield repair, headlight restoration, and engine component refurbishment. Due to their hardness, diamond abrasives maintain their shape and cutting efficiency for an extended period, ensuring consistent performance and exceptional results.

sia 7240 siacarat is the perfect Diamond abrasive for the Automotive industry.

Diamond Abrasives

Diamond abrasives are the hardest and most precise type of abrasive available. They offer superior performance in automotive applications that require fine detailing, precision cutting, and polishing.

Diamond abrasives excel in tasks like glass and windshield repair, headlight restoration, and engine component refurbishment. Due to their hardness, diamond abrasives maintain their shape and cutting efficiency for an extended period, ensuring consistent performance and exceptional results.

sia 7240 siacarat is the perfect Diamond abrasive for the Automotive industry.

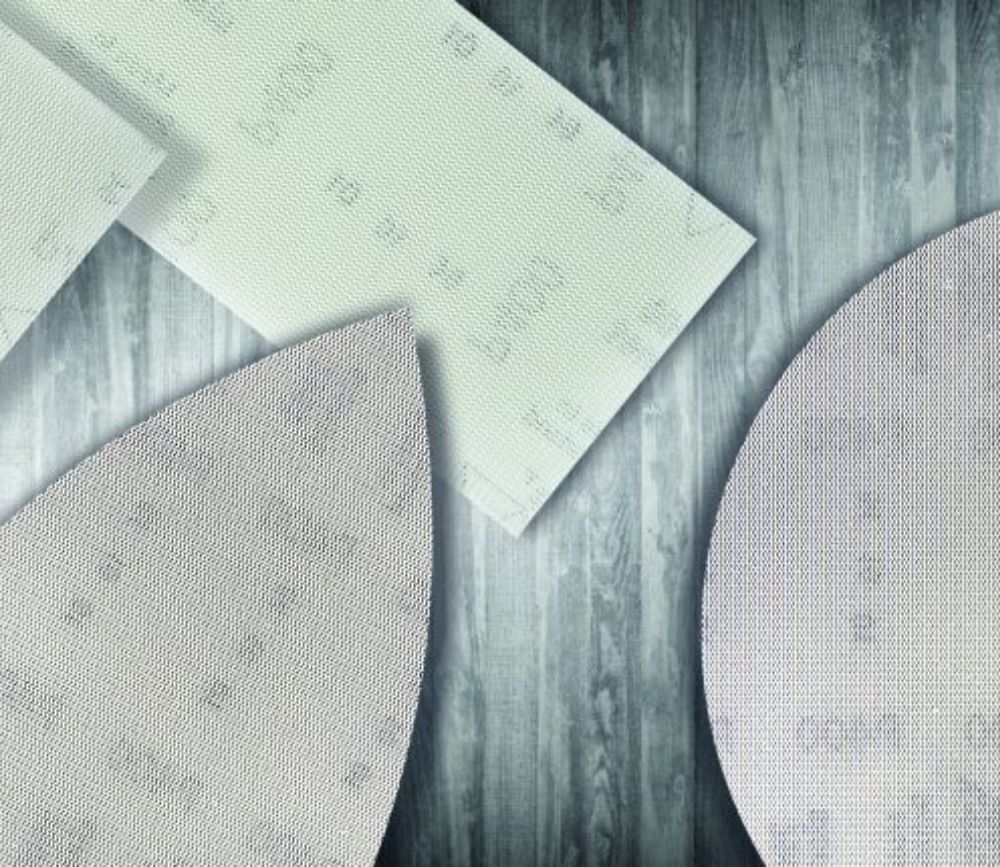

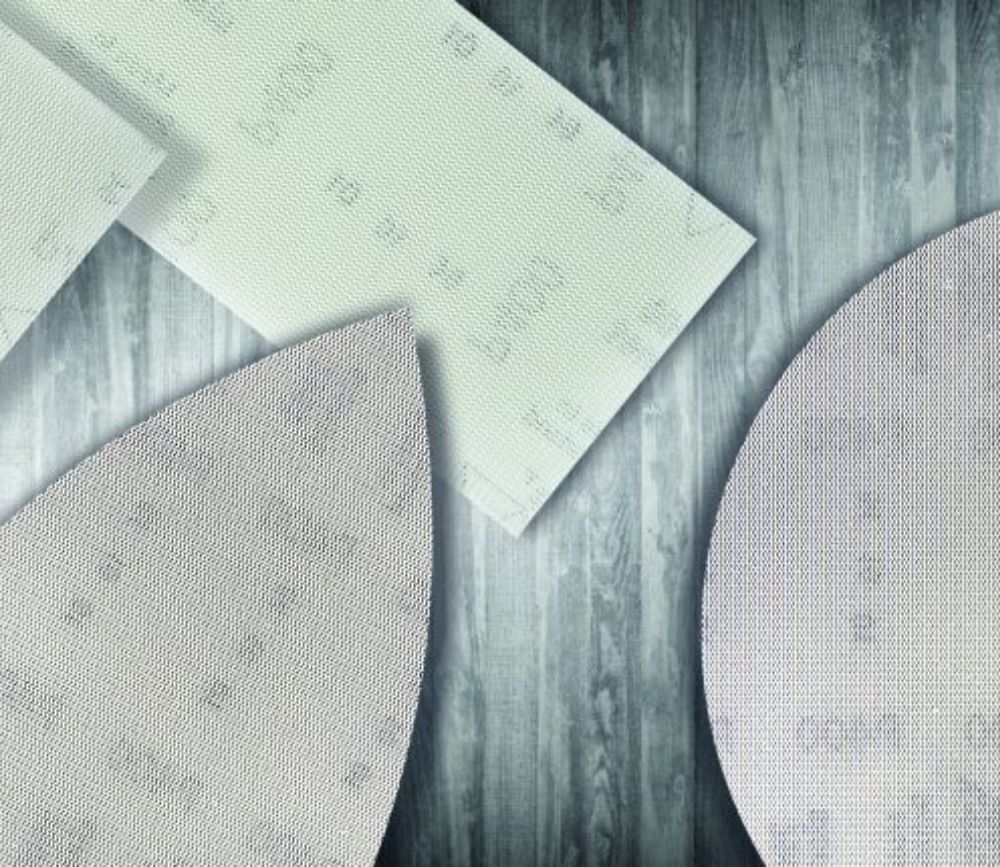

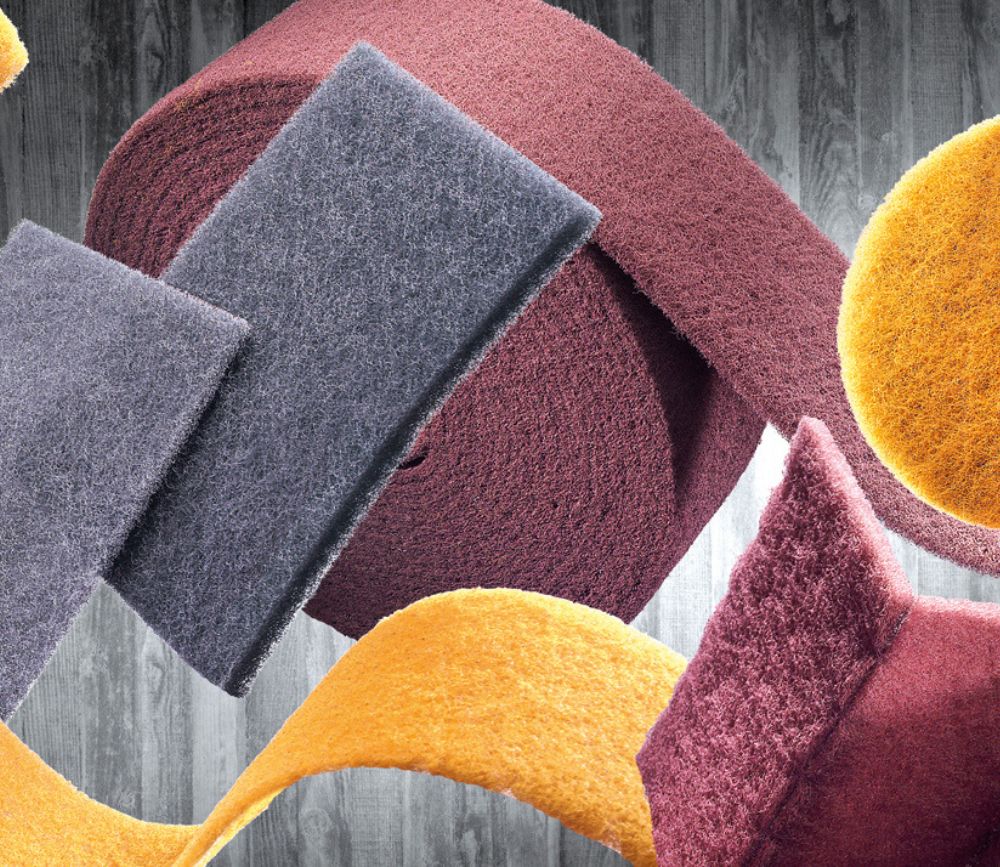

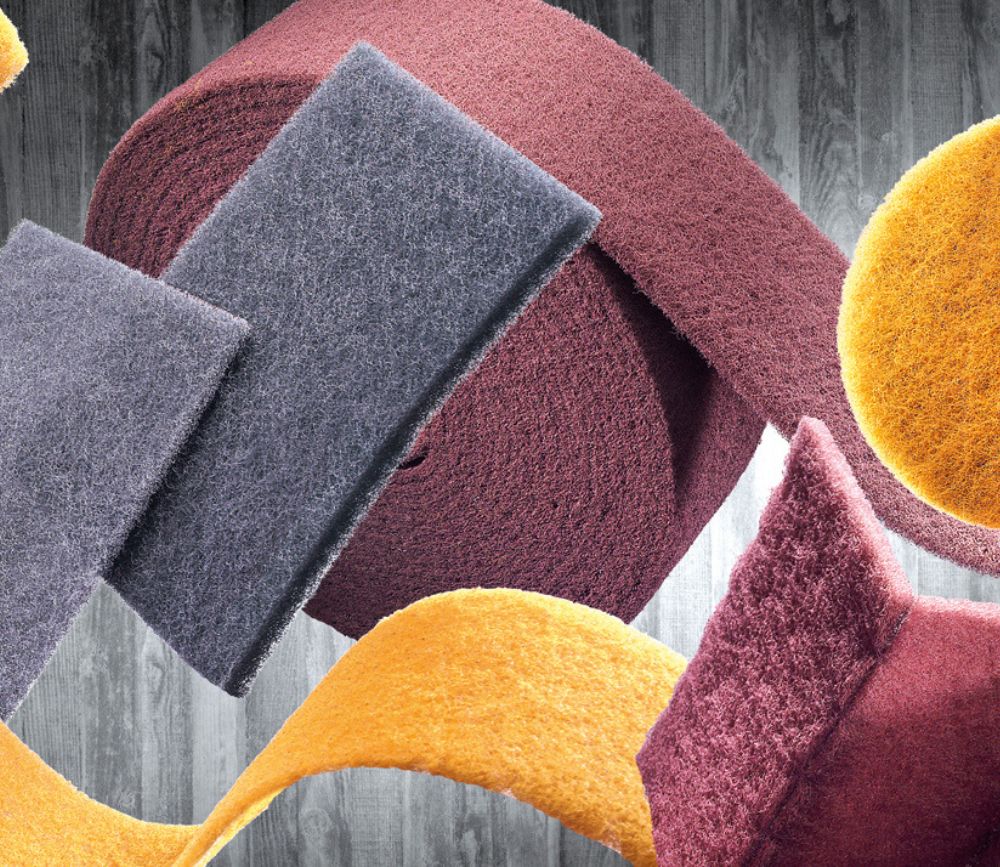

Non-Woven Abrasives

Non-woven abrasives are non-aggressive abrasives made of synthetic fibres infused with abrasive particles. They are excellent for automotive applications that require light deburring, cleaning, and surface blending.

Non-woven abrasives are commonly used for removing scratches, cleaning metal surfaces, and preparing surfaces for paint or coatings. They provide a uniform finish without altering the underlying material, making them ideal for delicate automotive components.

sia Abrasives 6120 siafleece is the perfect Non-woven abrasive for the Automotive industry.

Non-Woven Abrasives

Non-woven abrasives are non-aggressive abrasives made of synthetic fibres infused with abrasive particles. They are excellent for automotive applications that require light deburring, cleaning, and surface blending.

Non-woven abrasives are commonly used for removing scratches, cleaning metal surfaces, and preparing surfaces for paint or coatings. They provide a uniform finish without altering the underlying material, making them ideal for delicate automotive components.

sia Abrasives 6120 siafleece is the perfect Non-woven abrasive for the Automotive industry.

Choosing the right abrasive for automotive applications is crucial for achieving optimal results. Each type of abrasive has its unique properties and advantages, making it suitable for specific tasks.

Aluminium Oxide and Silicon Carbide abrasives are versatile options, providing excellent cutting power and durability. Ceramic abrasives offer extended life and heat resistance for demanding applications, while diamond abrasives excel in precision cutting and polishing tasks. Non-woven abrasives are perfect for light deburring and surface blending.

By understanding the characteristics of these abrasives, you can confidently select the most suitable option for your automotive projects, ensuring efficiency, quality, and the best possible finish.